CORPORATE SOCIAL RESPONSIBILITY

OUR COMMITMENTS Learn more

For several years now, as a major player in the manufacture of items for the home made of plastic materials, Grosfillex has committed a progressive approach aiming at reducing the environmental impact of its activities and at developing a virtuous ecosystem through 4 main fields of action

1/ THE ENVIRONMENT

Materials lifecycle I Circular Economy I Mastering natural resources I Mastery of energies

The use of sustainable and recyclable material for a longevity for decades of service.

A strong commitment to the circular economy and the use of recycled materials in new products.

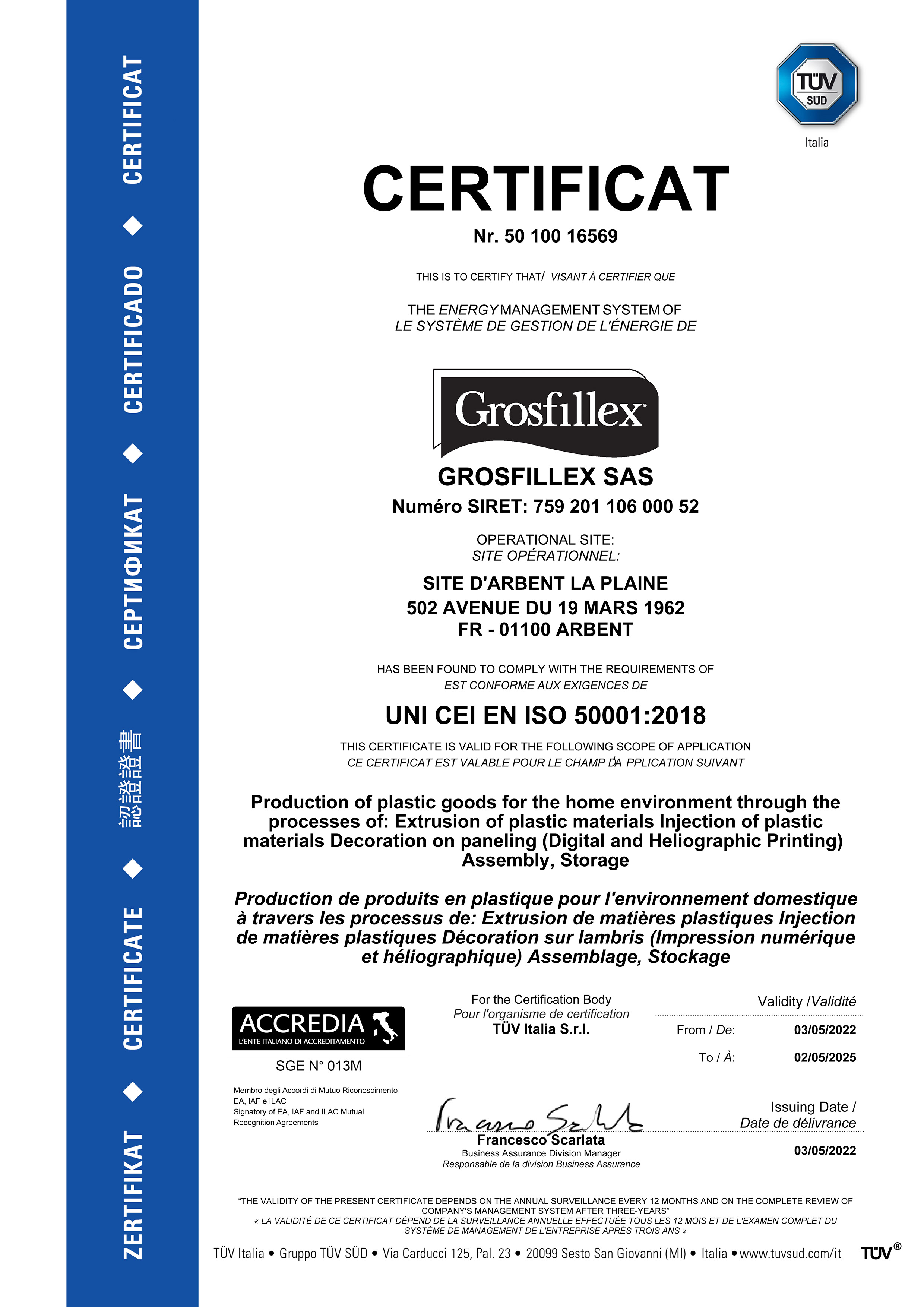

In 2022, in order to go further and involve all employees, the group has obtained ISO 50 001 certification (energy management) for "la Plaine" plant (France).

Find out more about the Group's energy policy HERE.

2/ WORKING RELATIONSHIPS AND CONDITIONS

Safety I Respecting the rights of individuals I Development for all

A quality work environment; safety first.

Discover our social charter and our HSE charter.

3/ FAIR PRACTICES AND RESPONSIBLE PURCHASES

Promoting CSR with partners I Purchasing Policy I Players in a committed network

A responsible French production in all its ecosystems

Find out more about our supplier charter.

4/ LOCAL COMMUNITY AND DEVELOPMENT

Regional anchoring I Local footprint

A family brand established in Ain for more than 95 years.